Electrical Power Transformer Specifications and its Applications

As the word “power transformers” is heard, the two things that strike one’s mind are efficient voltage regulation and smooth power conditioning. Though step-up and step-down are two popular types, there are still a lot more inventions to be explored in the field of power transformers.

Dating back to the 1880s, the property of induction was discovered and which in turn paved the way for the invention of transformers. Regular changes in its design have increased the overall efficiency and reduced its size to a large extent. In the 20th century, with the help of many technologies, the 800 KV transformers were developed and first introduced in the market.

What is an Electrical Power Transformer?

In simple terms, it’s a static machine that transforms electricity up or down between two circuits without changing the frequency. Since there are no rotating or moving parts, it makes sense to call it a static machine. The majority of the transformers operate in AC supply, but there are also few DC transformers prevailing in the market. The basic operational technique of the power transformers depends on the principle of mutual induction.

Why Do We Need An Electrical Power Transformer?

The primary work of an Electrical Power Transformer is to trade voltage for current without altering the total electrical power. So, it basically takes high voltage with a small current and changes it to low voltage with a large current and vice versa.

The two major works of any power transformer are to increase the voltage, in other terms, stepping up the voltage or decrease the voltage, which is also referred to as stepping down the voltage. The structure of the electrical power transformer includes two coils of wire with a large number of turns that are wrapped over a metal core. One coil corresponds to the incoming electricity whereas the other coil corresponds to the outgoing electricity.

The alternating current in the incoming coil results in generating an alternating magnetic field in the core which on the other hand generates an alternating current in the outgoing coil.

Normally lots of energy is wasted while transmitting electricity across a larger distance. To reduce the wastage of energy, the designers started using high voltage wires as a replacement for the low voltage wires.

Many risk factors were involved while using high voltage for home uses. In order to tackle this threat, Transformers were used to convert high voltage to low voltage before using it for home appliances.

During the initial phase, the voltage of electricity generated from a power plant is stepped up to withstand long-distance transmission. The Dynamos present in the power plants tend to produce high current but not high voltage. This is where the transformers come into play; they step up the voltage and make it easy for getting transmitted through wires.

As electricity needs high voltage for transmission, the process of stepping up the voltage plays an important role in the entire process.

Before the electricity reaches our homes, the voltage is stepped down using step-down transformers. This electricity can be directly used in our light bulbs or can be converted to DC for using it in laptops or computers.

In this entire process, 440-volt electricity is converted to the recommended 120-volt level and evenly distributed to suitable home appliances. Ever since the development of Power Transformers, it plays a vital role in the transmission, distribution, and utilization of AC electrical energy in all power appliances.

Specifications of an Electrical Power Transformer

Different features to look out for in an Electrical Power Transformer are listed below.

Phase

The two types are single-phase and three-phase. In a single phase, a single pair of coils is used. A primary coil and a secondary coil are used to generate the desired voltage. It has a less complicated design when compared to the three-phase transformers. Also, it produces an AC power supply of 1000 watts for the appliances.

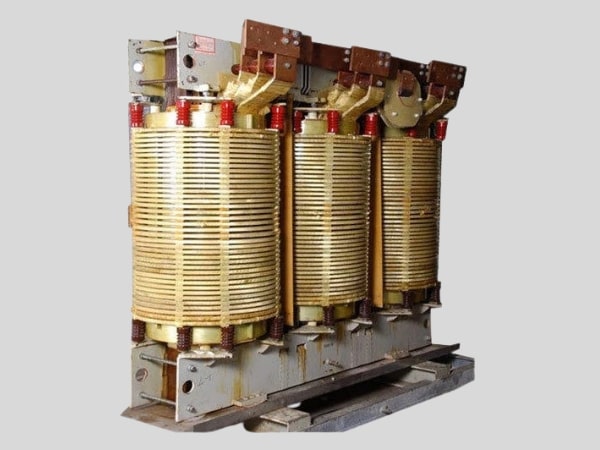

In a three-phase, three single-phase transformers are winded over a central core. The three-phase structure includes six coils, out of which three are primary and the other three are secondary. The usage of three-phase transformers reduces the risk level to a larger extent and also withstands more power loads.

kVA Rating

kVA stands for Kilovolt-Ampere and this rating is used to rate a transformer. The kVA rating for the single-phase transformers will not be the same for the three-phase transformers. The kVA of a transformer should be equal to or greater than the rating of the load. In other words, a 1 KW load would require a 1 kVA transformer.

Primary Voltage and Secondary Voltage

Primary voltage refers to the voltage that is applied to the primary winding of a transformer. If the primary has fewer turns compared to the secondary, the step-up transformer is used to increase the voltage. And, if the primary has more turns compared to the secondary, the step-down transformer is used to decrease the voltage.

Secondary voltage is the coil winding that supplies output voltage. The output voltage varies with variations in the load resistance and even with constant voltage input.

Full Load Current

The full load current is defined as the maximum allowable current to the winding. For calculating the full load current, the voltage, kVA rating, and the type (single-phase or three-phase) are required.

Vector Type

The different vector types are approved by the International electrochemical commission and they categorize the LV windings and HV windings configuration of the three-phase transformer. The difference in winding connections produces different phase angles between the voltage of the windings.

If the transformers are connected in parallel, the vector group should be the same to avoid circulating current and other system disturbance. Dyn 11 is a vector group notation of a transformer in which LV windings in star shape connection is 30 degrees lagging by HV winding which is delta connected.

Coolant type

- To dissipate the excess heat from the transformers, four types of cooling methods are used.

- Oil Natural Air Natural (ONAN): In this method, the heat produced from the core and winding is shifted to the oil.

- Oil Natural Air Forced (ONAF): Forced air is used to dissipate heat from the dissipating surface.

- Oil Forced Air Forced (OFAF): Oil flow is forced through heat exchangers. Airflow is also forced towards the heat exchanger.

- Oil Forced Water Forced (OFWF): It’s Similar to the OFAF method. The only difference here is, forced water is used to dissipate heat from the dissipating surface.

Also Read: 5 Things to Know Before you Buy a Power Transformer

The other specification of the transformers are as follows:

Dimensions

The dimensions of the Electrical power transformer include two main factors: the height of the window (Hw) and the width of the window (Ww). Two other important entities are the width of the largest stamping (a) and the diameter of the circumscribing circle.

Weight

For any transformer, the weight can be calculated by multiplying the transformer’s capacity in kilovolt amperes (kVA) with a basic impulse insulation level (BIL). The weight of core, winding, and oil for insulation can also be calculated.

Terminals

In a transformer, H terminal denotes high voltage, and the X terminal denotes low voltage. These terminals can either be primary or secondary based on which is the source and which is the load.

Serial Number

The serial number format printed in the transformers is usually used t0 identify information like the year of manufacturing, the month of manufacturing, date of manufacturing, and also the place of manufacturing.

Quality Standards

The International Electrochemical Commission (IEC) and the International organization for standardization (ISO) develop and propose the international standards which are to be followed by the firms in electrical, electronic, and all other related fields.

Applications of Power Transformers

Power transformers are widely used to operate different voltages at high power ratings. The other major role of the Power Transformers is to transmit and distribute electrical energy. In electronic circuits, the Power Transformers are used to accomplish various purposes.

The power generating plants, power distribution centers, and various other industries are largely benefited by using Power Transformers in their manufacturing techniques.

Its application is further extended to textile industries, Pharmaceutics, food manufacturing industries, Hydropower generation, nuclear power generation, thermal power generation, and also in the production of solar energy, wind energy, and biomass generation.

Conclusion:

Here at EVR Power, we’re determined to design high-quality Power Transformers by incorporating unbeatable standards. Our highly skilled team work towards attaining maximum customer satisfaction, technological excellence, and environmental consciousness. EVR Power dominates the technological market by building Power Transformers with optimum efficiency, excellent quality, and assured safety.